Last Updated on January 26, 2023 by Aaron

The Italian parmesan, also known as Parmigiano-Reggiano, is a hard, granular cheese that is made from raw cow’s milk. It is an iconic and beloved ingredient in Italian cuisine and is used in a variety of dishes from pasta to risotto to soups.

The process of making parmesan is a long and intricate one, that adheres to strict production guidelines, and it is only made in a specific region of Italy, the Emilia-Romagna region, which includes the provinces of Parma, Reggio Emilia, Modena, and parts of the provinces of Mantua and Bologna.

In this article, we will delve into the process of making authentic parmesan, from the sourcing of the milk to the stamping of the Parmigiano-Reggiano name, and everything in between. So join us as we take a journey through the production process of one of the world’s most beloved cheeses.

So, without further ado, let’s get started!

Table of Contents

Stage 1: Milk Preparation

The first stage of making parmesan cheese is milk preparation, which involves sourcing, collecting, heating, and preparing the milk for curdling.

The cheese is exclusively made from the milk of cows that live in the area and is fed with locally produced forage. The use of silage, fermented feeds, additives, and animal flour are banned.

The milk used for parmesan must come from local cow breeds of the Italian Frisona, Bianca Modenese (the white cow), Vacca Bruna (the brown cow or French brown), and Vacche Rosse (the red cow). The milk produced from each of these breeds will have slightly different characteristics, which can affect the final flavor and texture of the parmesan cheese. learn more.

For example, the milk from the Italian Frisona cow is the most common (was first introduced from Holland) breed used for parmesan making with high productivity. The brown cow milk parmesan is among the local favorite and features a high protein and fat content. And the parmesan cheese made from the milk of Vacche Rosse cows, also known as “red cow parmesan,” is considered to be a higher quality and premium version of the cheese — prized for its concentrated flavor and aroma, it is suitable for longer aging (minimum is 24 months for this type) than the milk from other breeds. Parmesan made from red cow milk has consistently been rated high in World Cheese Award, read more in our previous discussion of The Absolute Best Parmesan Cheese Brands article here.

However, it’s worth noting that the breed of cow is just one of many factors that contribute to the flavor and quality of parmesan cheese. Other important factors include the quality of the milk, the methods used to produce the cheese, and the aging process. All of these factors must be carefully managed and controlled in order to produce high-quality parmesan cheese that meets the strict standards set by Consorzio del Formaggio Parmigiano-Reggiano.

The milk is collected twice a day, in the morning and evening, and is transported to the dairy milk tank. Milk is prepared by mixing two consecutive milkings — the raw unpasteurized whole milk in the morning and the part skim milk from the previous day. The ratio is about one to one, and slightly adjusted to a fat content of about 2.5% (1).

The milk is not pasteurized but it is heated to around a temperature of 33–35 °C (91–95 °F) — this step is critical to set the foundation for the following production process whereby the temperature is suitable for the rennet (in the following stage) to work properly. Most traditional cheesemakers will use huge copper-lined cauldron vats for the process, as shown in the images below.

On the other hand, regular or domestic parmesan in the US will typically use pasteurized milk. While pasteurization is effective in ensuring that the food is safe to consume, it can also have an impact on the flavor of parmesan. Pasteurization can destroy the natural bacteria that contribute to the unique flavor of parmesan cheese, making it taste less complex and less flavorful. Read Parmesan vs. Parmigiano Reggiano.

Stage 2: Milk Coagulation – Curdling

Once the milk reaches the correct temperature, calf rennet is added to the milk. Rennet is a set of enzymes (such as chymosin, pepsin, and lipase) that helps to coagulate the milk and separate it into curds and whey. At the same time, the natural starter culture (whey) collected from the previous batch will be added to the milk.

The starter culture is a combination of specific bacteria which plays a crucial role in the milk coagulation process and in the development of the characteristic flavor and texture of parmesan cheese. The bacteria involved are mainly the Lactic Acid Bacteria (LAB) which ferment the lactose in the milk and produce lactic acid — this process helps to acidify (lower the pH of) the milk and ultimately coagulate and turn it into curd. The diversity of the bacteria which is only present in certain places in Italy is essential to dictate the development of the parmesan’s flavor, aroma, and texture. You can read more about the bacteria population in parmesan here.

For regular or common parmesan, most producers will use a mixture of LAB bacteria such as Lactococcus and Streptococcus bacteria as the starter culture to achieve a similar result (2). For homemade parmesan, the curdling process can also be initiated by adding an acidic substance, such as vinegar or lemon juice, to the milk.

The milk is then left to coagulate for about 15 minutes, during which time it slowly forms a solid consistency similar to custard. After that, a giant whisk tool called “spino” or “curd cutter” is used to cut the curds into granules, to release the whey. Now is commonly done using cutter machines.

Once it’s done, the temperature is raised and maintained at about 55 ºC (131 ºF) for another 45-60 minutes. Cooking will expel more whey from the curds. This temperature is similar to the “thermized milk” or “heat treating” the milk (which is still considered unpasteurized in the US) while maintaining the optimal flavor of parmesan and also eliminating the potentially harmful bacteria.

After the curds have been cooked and settled at the bottom of the vat, the next step in the process is to collect the granule curd mass.

Stage 3: Molding and Brining

The curds have now formed a compact mass and are ready to be collected. This is typically done by draining off the remaining whey and then scooping (using muslin cheesecloth) or cutting the curd mass out of the vat.

Once the curd mass has been collected, it is then placed into molds and weighted down to press out excess whey. Then, transfer into a cylindrical stainless steel metal wheel that is pulled tight with a buckle to give the cheese its final shape and to compact the curds further. The cheese is then left to sit in it for a period of time — up to a day.

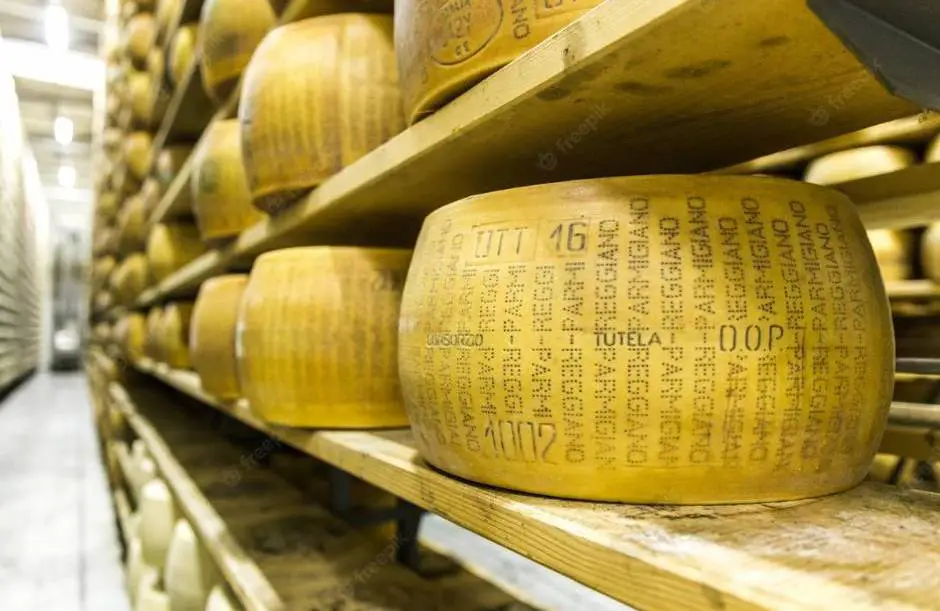

After that, a plastic belt is put around the cheese and buckled tightly into the metal again for another 2-3 days. The stenciled belt is imprinted with traceable product information, such as the “Parmigiano Reggiano” markings, date of production, and the batch & plant number which allows for easy identification and traceability of the cheese. Now they also include the “casein plate” that says CFPR which contains alphanumeric codes and QR codes for each wheel, where you can track back to the dairy and batch via the website page here.

The parmesan wheel is then placed in salt water (36% salinity) for about 20-23 days (3). Brining is an essential step that helps to add flavor to the cheese and also helps to preserve it — It is to give the cheese its characteristic saltiness and also helps to prevent the growth of unwanted bacteria. The brine also helps to create a specific microclimate around the cheese that favors the growth of desirable bacteria, which gives parmesan its unique flavor.

During the brining process, the cheese wheels are turned and moved around in the brine to ensure that they are evenly flavored and to prevent any unwanted bacteria from forming. Once complete, the cheese is drained and transferred to the aging facility to cure for a minimum of 12 months, during which time it develops its complex flavor and aroma.

Stage 4: Maturation – Curing

The crucial step in the process of making parmesan cheese is maturation, also known as aging. This is a critical step for parmesan, as it is during this time that the cheese develops its complex flavor and aroma. The legal FDA requirement for regular/domestic parmesan in the US is to cure for at least 10 months. While the Parmigiano Reggiano has a minimum of 12 months and is more often to be aged for longer — up to 36 months (Stravecchio) or above. Most Parmigiano Reggiano is typically aged for around 24 months.

During the maturation process, the cheese wheels are stored on special wooden shelves in aging rooms that are designed to provide optimal conditions for aging. These rooms are typically kept at a temperature of around 14-16°C (57-61°F) and at a humidity of around 75-85%. The cheese wheels are periodically turned and brushed to ensure that they are aging evenly and to prevent any unwanted bacteria from forming.

For 12-month parmesan, it is during this time that it develops its characteristic nutty, fruity, and slightly sweet taste. Parmesan aged for 18 months or longer is considerably more flavorful, and it has a flakier texture. Parmesan aged for 24 months or longer is considered to be of excellent quality, and it is known for its complex and intense flavor. Some artisanal parmesans can go for 100 months or more. The longer the aging, the parmesan cheese will develop a harder texture and deeper golden rind color, and also will taste fruitier or nuttier. It may also have more crunchy bits that look like white speckled clumps (see images in our previous discussion).

However, it’s important to note that while aging can bring out more complex flavors, it’s not always the case that older is better. It’s up to taste preferences and uses, where older parmesan tends to be stronger and concentrated for consumption in smaller doses. Some people prefer the younger and more delicate parmesan.

Most of the award-winning masterpiece of Parmigiano Reggiano is aged between 24-40 months. That’s the “just right” as it strikes a balance of optimal flavor.

We are not done yet! One last step to go…

Stage 5: Inspection – Grating

Parmigiano Reggiano goes through a final step called “grading” or “classification” before it is ready to be sold. During this step, a team of expert testers inspects each wheel of cheese to ensure that it meets the strict standards set by the Parmigiano Reggiano Consortium.

The testers evaluate the cheese based on its appearance, aroma, flavor, and texture, and assign it a grade based on their findings. Only cheeses that meet the highest standards are awarded the “Parmigiano Reggiano” designation and are allowed to bear the Consortium’s stamp of authenticity on the rind. Cheeses that do not meet the standards are sold as lower-grade parmesan-style cheeses.

During the parmesan cheese inspection process, experts or graders may use a variety of tools to evaluate the cheese and the pass rate is usually 85-90%. Watch the video on how it’s done. Some of the tools that may be used include:

- Cheese hammer: This small metal hammer is used to gently tap the cheese and listen for any sounds that may indicate defects or inconsistencies in the texture.

- Screw needle: A screw needle is a tool with a small, sharp point at one end and a handle at the other. The grader will use the screw needle to insert it into the cheese, taking a small sample of the cheese’s paste. It is to check for consistency and aroma of the cheese.

- Wedge: The wedge is used to remove a small piece of the cheese, allowing the grader to evaluate the paste of the cheese and check the cheese’s texture, color, taste, and overall quality.

Some of the common defects such as tears or cracks (surface splits), formations of “eyes” and dark spots. If the quality meets their standards and passes, it will then be fire-branded with the official “Consortium” mark, and be called and sold as “Parmigiano Reggiano.”

The consortium has set forth specific criteria for each grade:

- Classico: First & top-grade parmesan category. The finest grade of parmesan that passes the quality inspection and is iron-branded with markings.

- Mezzano: Medium-grade parmesan category. Small defects and should be eaten young. The rind has horizontal lines of parallel grooves indicating a strikethrough rind on the Parmigiano Reggiano markings. Some brands (on the packaging) will state it as the “Parmigiano Reggiano – Mezzano” certification mark.

- Scartone: Third category with serious defects. It will be “de-rind” — which means the entire rind with “Parmigiano Reggiano” will be removed.

There are several other classification labels such as “Export”, “Premium”, “Extra”, “Prodotto di montagna” and so on. The Extra (or sometimes Export) indicates the cheese has met high quality for export with 18 months of aging, while the Premium is 24 months. The Prodotto di Montagna label means the cheese is from the mountain area with 24 months of aging.