Last Updated on December 26, 2022 by Aaron

Cheddar cheese is a type of popular hard cheese made from cow’s milk. It has a mild flavour and smooth texture, with a sharpness that increases as it ages.

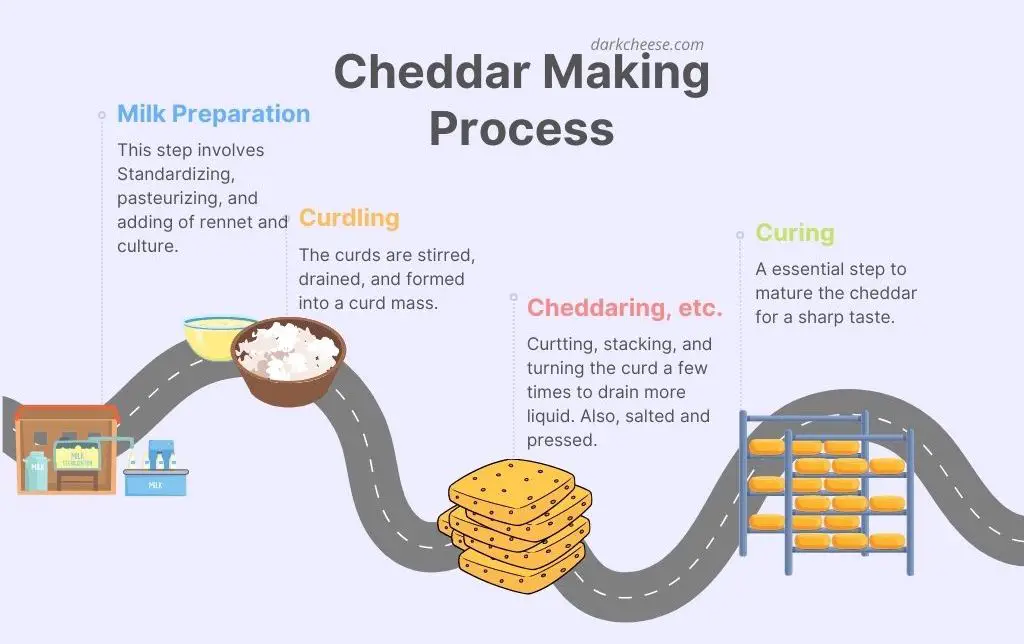

But do you know how it is made?

In this blog post, we will take a look at each step in making cheddar cheese. We’ll also discuss some of the commonly asked questions about cheddar below.

So without further ado, let’s get started!

Table of Contents

Step #1 – Milk Preparation

The first step in making cheddar cheese is to collect raw cow milk from the farm. For most farmstead and artisanal cheesemakers, raw milk is sourced directly from their own local farm or the closest farm possible for freshness. This is a crucial step to ensure the quality of the milk — which will directly impact the cheese flavor.

Also, cattle eat a slightly different proportion of diet (of forages) throughout the season and they eat other things too. Therefore, the taste of the cheese may not be always the same.

Once the milk is collected, it doesn’t go straight into cheesemaking just yet. Most modern dairy factories will go through a process called milk standardization to adjust the ratio of fat and solid in milk. It is for legal requirements — where cheddar must contain no less than 50% milkfat and maximum 39% moisture, according to FDA Regulations. In this way, the cheese flavor will be more consistent for each batch.

When it’s done, the milk will be ready for pasteurization.

Step #2 – Pasteurization

Pasteurization is the heat treatment process, which kills off any harmful bacteria and enzymes that can spoil the cheese and causes food-borne illness. In traditional cheddar cheese making in England and some european countries, raw or thermized milk (milder heat-treated milk) is permitted to use without pasteurization — for a better cheese flavor. Read our discussion on different types of cheddar taste.

In the United States, however, most commercial cheddar cheesemakers use pasteurized milk for safety and legal reasons.

For the pasteurization process, the raw standardized milk is first heated to around 71°C (160 °F) for 15 seconds, or 63 °C (145 °F) for 30 minutes. Pasteurization will also alter the composition and structure of the milk proteins (1). These may affect how the cheddar curd coagulates, the cheese texture and the melting ability.

After pasteurization, the milk is set to cool down and later transferred to a holding tank.

Step #3 – Adding the Starter Culture

Milk acidification is done by adding the starter (bacteria) culture to the milk. The starter culture is a mixture of natural lactic acid-producing bacteria, which can be obtained from the previous batch of whey leftovers. Most American-style cheddar often uses mesophilic culture, some producers might also add thermophilic bacteria.

This step is important in acidifying (lowering the pH of) the milk, which helps coagulate the curd. This slightly acidic environment is also promoting certain favorable bacteria to grow.

The selection of starter culture will have an impact on the final flavor of the cheese. For example, the common bacteria strains for cheddar making are Lactococcus lactis ssp. lactis and Lactococcus lactis ssp. cremoris.

The L. lactis is particularly more heat-resisting so it will tend not to be retarded/deactivated in the process — thus, resulting in better efficiency. However, it may also cause a bitter taste in cheddar which is a common flavor defect (3).

It’s worth mentioning that this bacteria strain produces very little to no carbon dioxide (2). Therefore, you will rarely see big holes in cheddar cheese as in Swiss cheese.

Most producers will use a set of starter cultures or a selected few. Therefore, different brands of cheddar cheese will usually taste or texture somewhat differently.

After the starter culture is added, the milk is allowed to rest for about 40 minutes to allow the bacteria to do the work.

Step #4 – Adding Rennet

Together with the starter culture, rennet is also added to the milk. Rennet is a set of enzymes that comes from the stomach lining of calves (and sometimes other ruminant mammals).

The enzymes help to “glue” the curd by cutting the casein protein “hairs” in between the molecules. The milk is then allowed to rest for about 35 minutes. And meanwhile, you will see the curd solidify slowly in the vat.

Nowadays, most commercial cheese brands are using microbial rennet (FPC chymosin, which is usually labeled as “enzymes”) instead of animal-sourced rennet. If you are a vegetarian or plant-based eater, we’ve discussed cheddar rennet and vegetarian here.

Step #5 – Cutting the Curd

When it’s about time, the experienced cheesemakers will poke the curd with their fingers and check to see if it’s ready — they are looking for a “clean break”. Once it’s ready, the cutting process can begin.

Cutting is done by using a large metal harp or similar tool to slice through the curd. Cheddar is a hard, aged cheese so we want it to be drier. Cutting smaller curds will help to release more whey, increase the surface area for moisture loss and assist with draining.

Nowadays, most commercial brands use a mechanical cutter that is designed to cut and stir automatically — it can also save time of manual labor. The curds are usually cut into small grain-size cubes (around 1 cm in size).

Step #6 – Stirring and Heating (Scalding) the Curd

Meanwhile, the grainy curds in liquid whey are then stirred gently (not vigorously) and heated to around 40°C (104 °F) for about 30 minutes. The temperature is great for rennet to work at its optimal.

Also, the mild heating of curds is important because it will allow the curd particles to contract and expel more whey. At this point, the curd particles stick to each other and sink to the bottom of the vat forming a mass, and the whey should be yellowish and cloudy.

The next step is to drain the whey and scoop up the curds.

Step #7 – Cheddaring

Once drained, the curd mass is allowed to settle on a clean surface (frequently a draining table) and the cheesemaker will start the cheddaring process — which is basically cutting, flipping, and stacking curds repeatedly.

The idea behind this step is to expel more whey from each individual curd particle so that they can bond together better in forming “blocks” of cheese curd.

The curd slabs are piled on top of each other. Then they are folded over again and re-stacked before being placed in one big block, cut up and repeated. The entire cheddaring process usually takes about 1-2 hours. At this point, the cheese curds will have a slightly rubbery and pliable texture.

As more whey is drained, this step is important to develop acidity where workers will have to check the pH of the cheese regularly until it reached about 5.2 to 5.3.

Some other cheddaring processes will also add warm/cold water to wash the curds and dilute the whey. This will further lower the lactose content and acidity, resulting in sweeter softer less-sharp cheddars similar to Colby. You can read our previous discussion on Cheddar vs Colby.

Step #8 – Milling and Salting

When the cheddaring process is over, the curd blocks are then milled (or cut) into 1-inch small pieces before being placed in a large hopper. The curds will be mixed with salt and stirred to ensure that the salt is distributed evenly throughout. Then, allowed to rest for about 10 minutes.

The salting process helps to remove more moisture from the cheese, as well as enhances flavor development throughout the aging period. Salt is also a natural preservative.

The salt content is usually about 1-3% ratio to the weight of cheese curds. The salt content will determine the cheese’s firmness and bacteria activity. Too much salt may retard the bacteria’s growth, while too little can cause a softer texture. You’ll want it to be just right.

Step #9 – Molding and Pressing

Finally, the salted curds are transferred to molds or hoops. The molds will help shape the cheese and expel more whey — which will be pressed by a mechanical or vacuum press for about 16 hours.

The pressed cheddar cheese will become more compact and firm. It will then be left to dry for a few days. Waxing may be done during this time to create a barrier and also to prevent the growth of mold on the surface.

The same goes for clothbound, bandaged wrapped traditional cheddar. The cloth assists with aging and prevents the cheese from losing moisture too quickly and also serves as a first barrier, while still allowing the cheese to “breath” — important for bacteria activity!

Step #10 – Maturing or Curing

The aging process will follow thereafter as the cheese develops its flavors and texture. The desired characteristics can be determined by the length of time it’s aged — generally ranging from 3 months to 2 years or more for extra sharp cheddar cheeses.

The maturation takes place in a controlled environment (e.g. cave or insulated room) and the cheese must be regularly monitored for any possible contamination. The temperature is usually around 4-14 ºC, where maturation at 12 ºC (~53 ºF) is considered to be optimal (4) and relative humidity lower than 80%.

The good aging process also helps to foster bacteria activity which will help create more complex flavors. Throughout the curing stage, the cheese will be evaluated for texture, smell, and taste.

Once the cheese is properly aged, it will then be packaged and shipped off to its destination. And there you have it — that’s how cheddar cheese is made! Now you know what goes into making one of the most popular types of cheese in the world.

Questions for Cheddar

Is cheddar cheese real cheese?

Yes, cheddar cheese is a real cheese that has been made since the 12th century in the English village of Cheddar. It’s one of the most popular cheeses in the world and can be used in a variety of dishes. Cheddar is a hard cheese made from cow’s milk and is aged for an extended period of time, giving it its sharp flavor.

There are several different types of cheddar cheese, including mild, sharp, and extra sharp. Mild cheddars have a creamy taste and are usually aged for only a few months. Sharp cheddars have a full flavor, are tangier and are aged for up to two years or more.

What are the ingredients in cheddar?

The ingredients of cheddar cheese include cow’s milk, starter bacteria, rennet (an enzyme that helps the milk to separate), salt (for flavor and preservation), and other additives such as annatto (a natural food coloring). Some other ingredients such as modified food starch (prevent cheese to clump together) might be present in pre-shredded packaged cheddar. Always go for all-natural block cheddar.

Why cheddar cheese is orange/yellow/white?

The color of cheddar cheese can be ivory, buttery yellow or orange color. The color is because of the coloring agents added — annatto typically. Some common agents are plant extracts such as beet juice, spice annatto, or oleoresin paprika. Without coloring, cheddar cheese is always ivory or off-white.

What is the difference between English Cheddar vs American Cheddar?

Cheddar cheese is made in a similar way all over the world, but there are some regional differences. American cheddar cheese is often milder and less complex in flavor, while English cheddar is usually aged for longer, giving it a richer flavor. Also, English cheddar is often cylindrical in shape and clothbound.

Can cheddar cheese have holes?

Yes, cheddar cheese can have tiny holes or “eyes” sometimes but mostly “blind” without holes, as too many holes can be considered a defect. It is due to the lactic acid bacteria strains added to the production. One of the most common is called Lactococcus lactis. It is a homofermentative bacteria that don’t produce as much carbon dioxide and may even inhibit the gas production of other bacteria.

Reference:

- Nassar, Khaled & Lundin, Josefin & Iordache, Flavian & Hailu, Yonas & Mengistu, Habtamu. (2015). The production of Cheddar cheese. 10.13140/RG.2.1.4958.2801. source